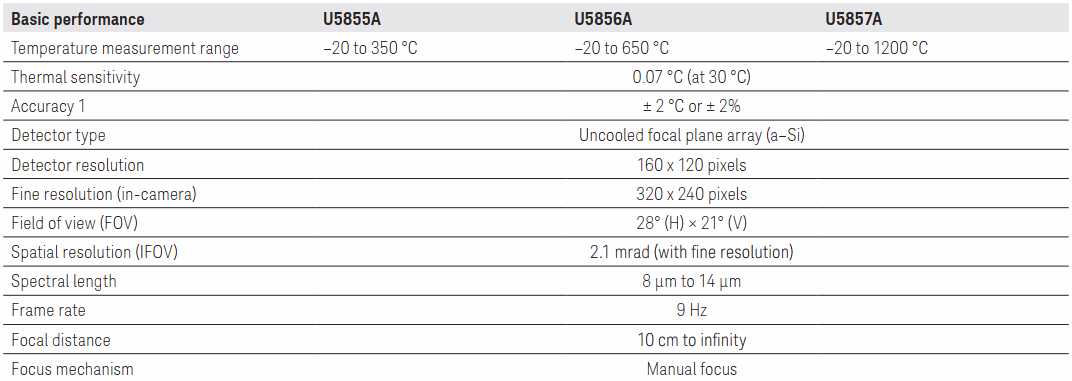

Keysight U5850 series TrueIR Thermal Imagers

Confidently detect problems with four times better resolution

Contents

Why use thermography?

Every object that is above absolute zero temperature emits infrared radiation. This phenomenon enables us to use thermography, which detects the infrared radiation from an object and produces the image of the radiation which is called a thermogram, IR image or thermal image. A thermal image effectively tells the surface temperature of an object, depending on the amount of radiation that was received. Over the years, thermography has evolved from being used as merely a tool for surveillance and military to a wide variety of applications, such as predictive maintenance to monitor the health and condition of an object, home or building inspections, medical, equipment and many more. Here are some of the common application settings:

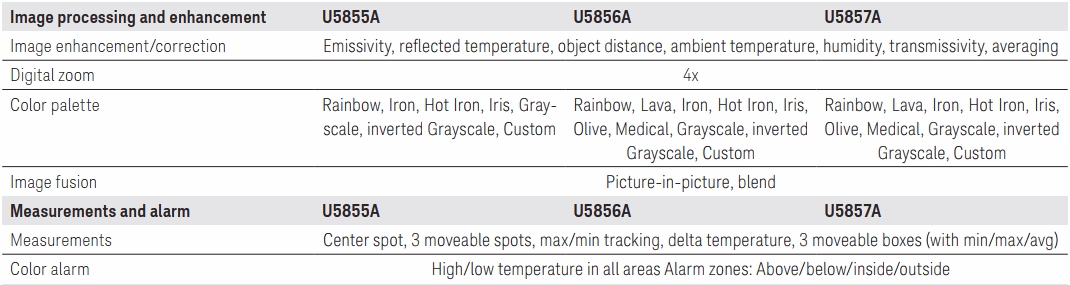

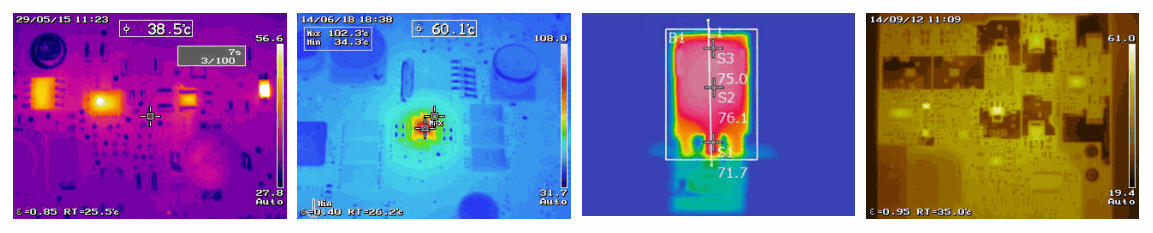

Predictive maintenance on electrical and mechanical systems

In predictive maintenance environments, thermal imager is used to perform mechanical and electrical inspections on motos, pumps, switch gears, circuit breakers, and the like. Hotspots as shown in the infrared (IR) images above indicate there may be a loose connection or a specific component is about to breakdown. These indications are warning signs which help to eliminate potential problem.

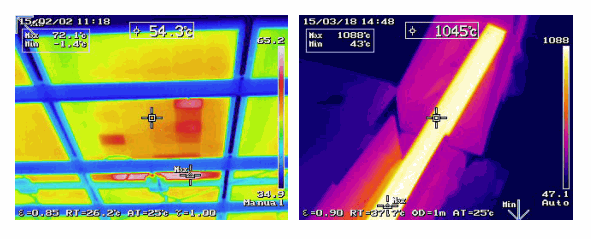

Commercial or residential building inspections

With the continued urbanization which drives constructions of commercial and residential buildings, it creates a demand for building inspections and maintenance. The U5850 series TrueIR thermal imagers come in handy to perform both interior or exterior structural building inspections such as air infiltration, condition of floor heating elements, moisture on ceiling tiles, as well as uneven roof surfaces. This is essential to assure compliance with the plans, check on workmanship and code compliance.

Electronics design and troubleshooting

One of the fastest ways to troubleshoot design and manufacturing quality issues on circuit board is through physical inspection. Traditionally, this is done by touching the surface of the circuit board to check for hotspots. However, this technique could be dangerous when used on high voltage circuits without proper safety precautions. This is where the thermal imagers come in handy. With the ability to measure temperature distribution over the whole circuit board, R&D and process engineers now can quickly inspect the circuit board to find thermal anomalies without having to touch it - non-contact temperature measurement.

In the field of electronics design, test engineers utilize the thermal imager to perform temperature characterization on electronics circuit designs, devices, systems and power electronic modules.

Other applications

In fact, thermography can be used for many other applications such as automotive, medical, equine, metal processing, chemical processing or even renewable energy systems such as photovoltaic systems.

Keysight’s U5850 series TrueIR Thermal Imagers

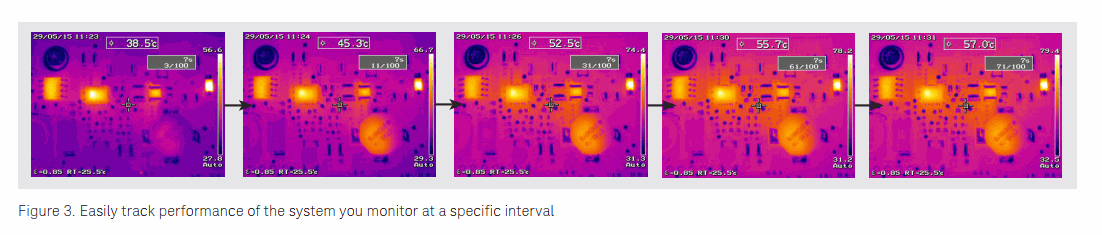

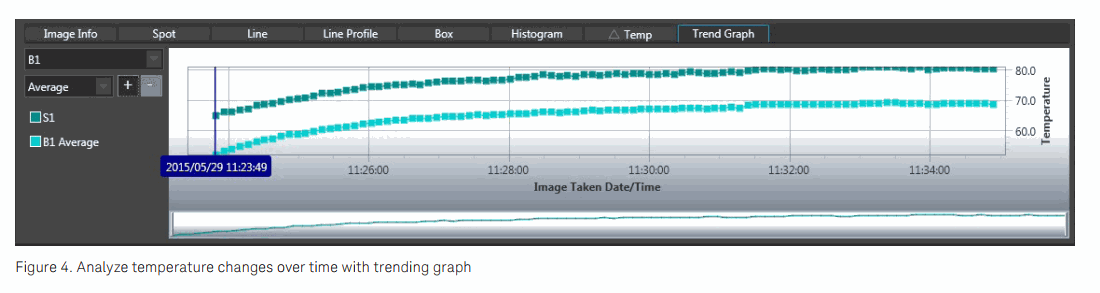

Detect potential problems faster with the higher resolution and affordability of our TrueIR Series of thermal imagers. Only from Keysight Technologies, can you get four times more in-camera fine resolution of 320 x 240 pixels from its detector resolution of 160 x 120 pixels. With the built-in image logging capability, easily track the performance of the system you monitor at a specific interval. Plus, you can analyze temperature changes over time with trending graph. Coupled with the powerful manual focus feature, users can focus on an object as close as 10 cm away - our solution provides clearer, sharper and reveals even finer details.

– Identify abnormalities faster with four times more in-camera fine resolution.

– Monitor temperature changes through image logging and temperature trending capabilities.

– Compact, lightweight, ergonomic.

– High-temperature range (up to 1200 °C).

– Easy-to-use customizable color palette.

– Single-handedly change settings with the configurable quick access buttons.

Fine resolution

Fine resolution is a technology that restores the details originally inherent to the object while enhancing the resolution, at the same time minimizing fuzziness and noise. It is accomplished by performing sophisticated calculations on continuous multi-frames of the image itself. The goal is to evaluate for misalignment caused mainly by hand tremors or shaking of the hands. Next, the firmware detects and corrects the information between images through one feature pixel resulting in clearer and sharper (IR) thermal images.

How fine resolution works

The figure below is a simplified model of the fine resolution process. Each step of the process is designed to handle different tasks. The multi-frame acquisition provides the images or data for processing at the next level. Super-positioning analyzes and merges all of the data together to prepare for reconstruction, where final touches are made to ensure a clear and sharp image is produced – resulting in a thermal image with four times more effective resolution.

The Multi-frame acquisition

– Continuous capture of multiple IR frames of images of the same scene assuming each frame will be slightly shifted due to natural hand movement.

– With fine resolution, all frames are up-scaled to higher resolution images (from 160x 120 pixels to 320x240 pixels) using the interpolation technique. This technique expands the image pixels by using data from adjacent pixels captured through a low-resolution detector – resulting in the interpolated high-resolution image as displayed on the LCD screen.

The Super-position

– Identifying a set of common feature points of each frame.

– These feature points form a register map representing common identities of all frames where they are aligned properly before being superimposed together to form a high-resolution image (refer to illustrations below).

The Reconstruction

– A process to enhance and sharpen the final thermal image.

– Techniques used: Averaging algorithm for noise reduction and edge enhancement algorithm to sharpen the image.

This fine resolution capability in the TrueIR thermal imager effectively improves the thermal resolution by four-fold using complex algorithms on a lower resolution detector. Coupled with a powerful digital image processor, the complex algorithms can be processed without any system lag. In short, fine resolution improves the effective image quality and measurement accuracy without adding much cost to overall thermal imaging system.

With fine resolution, you’d get:

– An effective 320 x 240 pixels of radiometric JPEG IR image which is much clearer and sharper

– Finer details on objects as close as 10 cm away, especially when measuring temperature on small components which is close to each other

– Four times digital zoom to magnify a thermal image of a far-away object to quickly identify anomalies and to reveal finer details.

Image logging and temperature trending

Image logging is a built-in capability where the thermal imager is able to capture thermal images at a specified interval. There is an option to input the number of images to be captured and set specific interval in between images. Users conducting temperature profiling on their design, performing equipment failure analysis or monitoring machine performance will find this feature useful, especially with the easy-to-use TrueIR Analysis and Reporting Tool. This software will enable users to plot the trend graph easily for instantaneous result.

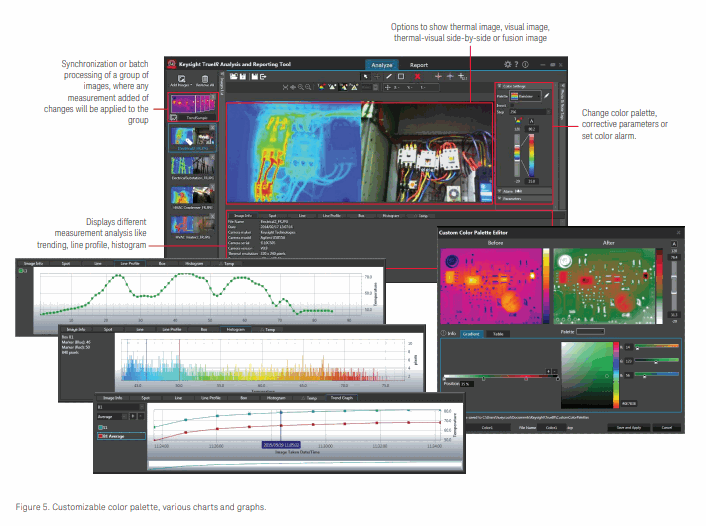

TrueIR Analysis and Reporting Tool

Generating a report for your clients is as important as capturing the IR image itself. With the help of Keysight’s TrueIR Analysis and Reporting Tool software, you are able to import, analyze, edit and present your report to your clients swiftly.

Features:

– Change color settings and corrective parameters, like ambient temperature, atmospheric temperature, or local emissivity of spot, box or line.

– Supports synchronization of IR images (batch processing) for temperature trending analysis.

– Create custom color palettes that are suitable for your applications.

– Set color alarm.

– Choose between six measurement analysis tools or diagrams like spot, line, line profile, box, histogram and delta temperature.

– Capable of displaying thermal image, visual image, thermal-visual side-by-side, or fusion images including as its associated photo or note tags.

– Create reports in Microsoft Words or PDF formats, based on available templates.

– Eleven local languages to choose from – English, Spanish, Italian, French, German, Portuguese, simplified Chinese, traditional Chinese, Japanese, Korean and Russian.

Take images as close as 10 cm away

The thermal imager’s powerful focusing mechanism lets you take clear thermal images from as close as 10 cm away. Now you can easily characterize temperature measurements on small components which are close to each other, yet being able to significantly single out each component or wire clearly.

The TrueIR thermal imagers provides clearer, sharper and reveals finer details so that problems can be detected even faster.

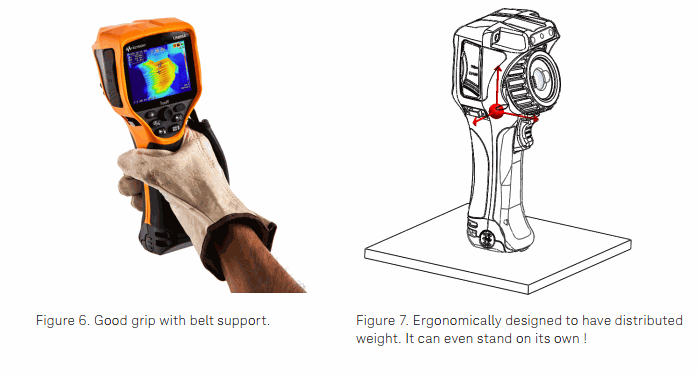

Ergonomically designed for comfort, compact, light-weight

The ergonomically built TrueIR thermal imager is designed to let you carry out daily tasks comfortably. With its evenly distributed weight of only 746 grams and good stability, it fits comfortably in your palm without straining your hands, even when used over a long period of time. With a stable grip, it allows you to single-handedly capture more images and to work more efficiently.

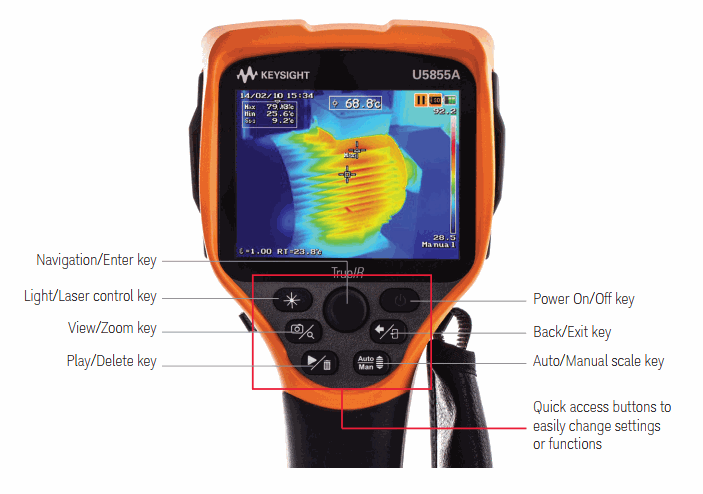

Configurable quick access buttons

Get the functions you want easily with the quick access buttons to frequently used functions such as Auto-scaling, trigger, flashlight and laser pointers

With the intuitive setup, now you can carry out thermography job easily without having the need to fumble over layers of menu. With just one hand, users can also customize camera, trigger, or playback settings. Let the U5850 series thermal imagers work for you, not the other way around.

Recommended accessories