Grinding

Removing and Installing Grinding Wheels on a Grinding Machine Is Simple but Often Overlooked

Grinding machines may appear simple, but they belong to a category of equipment that can suffer rapid wear if handled incorrectly. Many workshops experience wheel vibration, abnormal spindle heating, or early wheel cracking due to improper removal or installation, even though the operation feels routine. Understanding the machine structure and working principle helps prevent hidden issues that lead to costly repairs.

How a Grinding Machine Works and Why Correct Wheel Installation Matters

Unlike handheld grinders, a grinding machine uses a fixed spindle with direct drive from the motor to both sides. This means that even minor misalignment of the grinding wheel directly affects the spindle and bearings.

A wheel installed off center or tightened unevenly can cause continuous vibration. Vibration not only degrades grinding surface quality but also accelerates bearing wear and increases motor temperature beyond design limits. For this reason, wheel removal and installation directly impact machine lifespan rather than being a simple replacement task.

Grinding Machine Structure and the Role of Each Component

The central motor maintains stable rotational speed for both ends of the spindle. The two grinding wheels typically have different grit grades, one for rough grinding and the other for surface finishing. Each wheel is equipped with a protective guard and a spark shield to reduce the risk of metal debris reaching the operator.

The machine base, often underestimated, plays a critical role in vibration control. Improper positioning or uneven bolt tightening can cause off axis loading on the spindle during operation.

The main advantage of a grinding machine is its ability to operate continuously and stably at a fixed location. It is suitable for rough grinding, burr removal, tool adjustment, and metal surface preparation before finishing. In mechanical workshops, the machine is usually placed in a support area for quick processing of small parts without using larger equipment.

Common Mistakes When Using a Grinding Machine:

Many operators press the workpiece aggressively against the wheel to grind faster. In practice, this causes localized overheating, increases the risk of wheel cracking, and shortens wheel life. Another common mistake is grinding repeatedly at one spot, which leads to uneven wheel surfaces and vibration during rotation.

Some users remove the eye shield because it obstructs visibility. This is a frequent cause of accidents due to metal debris and sparks rebounding toward the operator.

Related article: Is sharpening drill bits with a double-wheel grinding machine difficult?

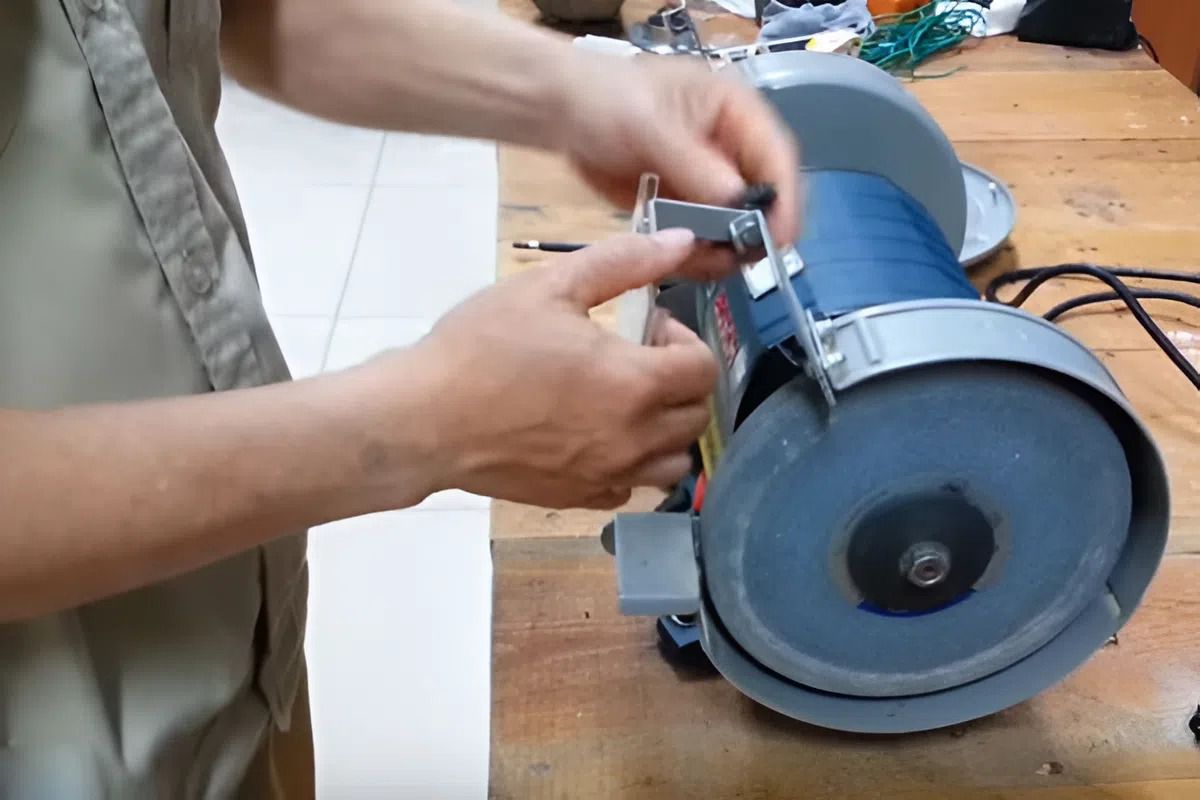

Proper Grinding Wheel Removal and Installation to Prevent Vibration and Cracking

Before any operation, the machine must be completely disconnected from the power supply. When removing the wheel guard and spark shield, screws should be kept organized to ensure correct reassembly.

Because both wheels share the same spindle, the opposite wheel must be secured when removing one side. The retaining nut is typically self tightening in the direction of rotation, so it must be loosened in the correct direction to avoid spindle jamming. After installing a new wheel, rotate it by hand to check balance and clearance before running the machine.

Running the machine without load for a few seconds helps detect abnormal vibration early. If vibration occurs, stop the machine and recheck the order of washers, spacers, and the tightening of the retaining nut.

Why Periodic Grinding Wheel Inspection Is Necessary

Grinding wheels that wear unevenly or develop small cracks are difficult to detect visually when the machine is stationary. During rotation, these cracks can propagate rapidly and lead to wheel failure.

Regular inspection enables early detection and timely replacement, reducing risk to the operator and minimizing wear on the spindle assembly.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-