What do you know about deadbolt pliers?

Deadbolt pliers are metal hand tools, consisting of two beaks and two crossed pincers, capable of holding objects firmly. With a special design, this type of pliers is widely used in fields such as mechanics, industry, shipbuilding and many other technical fields. In this article, we will learn in detail about the structure, outstanding features and practical applications of deadbolt pliers in production and construction.

Contents

Basic structure of crimping pliers

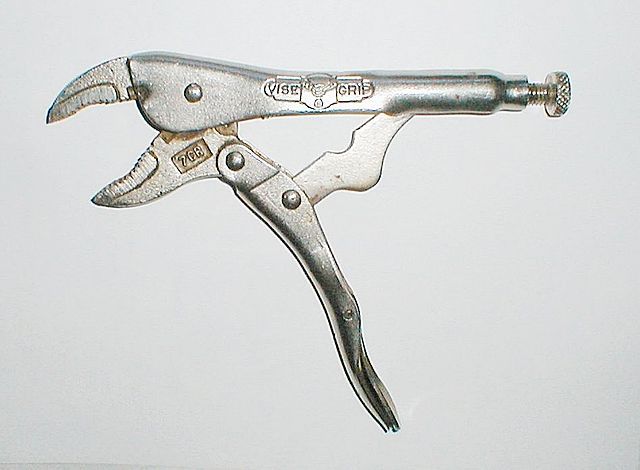

The crimping pliers have a simple design with three main parts:

Handle: Usually made of stainless steel, the handle is designed to fit, easy to grip and has good heat and electrical insulation. Thanks to that, users can operate easily with just one hand, increasing flexibility when working.

Clamp: This is the part that directly contacts the object to be clamped. The clamp is equipped with an adjustment button to suit the size of the object, and has a sturdy locking mechanism to hold the workpiece tightly. Currently, there are many different types of clamps such as semi-circular curved clamps (one side is curved, one side is straight), triangular beveled clamps, flat clamps or clamps with two curved points... Of which, the semi-circular curved clamp is the most popular thanks to its ability to flexibly adapt to many types of objects.

Pliers blade: The blade is designed with wavy serrated teeth, helping to increase grip when clamping and limit slipping during use.

Outstanding advantages of dead crimping pliers

In the toolkit of any craftsman, crimping pliers are almost an indispensable item. Although compact, this tool has many valuable advantages:

Crimp pliers are made from durable alloy steel, compact design, easy to hold and can be operated with just one hand. This makes repairing electrical, water or sanitary systems more flexible and convenient than ever.

Diverse in design, crimping pliers can adapt to many different types of workpieces - from round, flat to special details.

The clamping jaw can be flexibly adjusted according to each need, helping to hold details of different sizes, creating safety and precision when operating.

Practical applications of crimping pliers

Thanks to the ability to hold the object firmly, the worker can comfortably cut, press or edit with one hand without having to hold the object tightly.

Easily clamp pipes, steel wires, round blanks of moderate size - all are locked firmly and securely.

Pliers can be used to hold the details when disassembling, or temporarily fix the parts to handle the next steps.

The dead clamp also maximizes its function when used to tighten, twist, twist, cut electric wires, thin steel wires or other small details.

Conclude:

Hopefully, the brief but practical sharing from EMIN has given you a clearer view of the uses and practical benefits of dead-end pliers. Thank you for watching!